Accurate scratch-dig inspection is essential for maintaining quality across optical manufacturing. Standards such as MIL-PRF-13830B and ISO 10110-7 (visibility) rely on optical reference standards that allow inspectors and automated inspection systems to evaluate surface defects with consistency. These reference standards serve as the basis for grading defects, determining whether a part meets specifications or needs to be rejected.

To ensure effective quality control, reference standards must be highly consistent and trustworthy. Any variation in these sets can lead to inconsistent grading, which in turn impacts production quality. If reference sets differ between manufacturers, or even between inspectors within the same facility, it can result in misclassification of defects, leading to unnecessary rejections or, conversely, substandard parts passing inspection.

Producing repeatable reference sets for MIL-PRF-13830B and ISO 10110-7 has long posed challenges due to the complexity of precisely replicating microscopic surface defects on glass. While existing standards have helped improve industry practices, variability remains an issue. Inconsistencies across reference sets can create disparities in inspection results, affecting the reliability of optical components throughout the supply chain. For an overview of commercial standards, please refer to this summary.

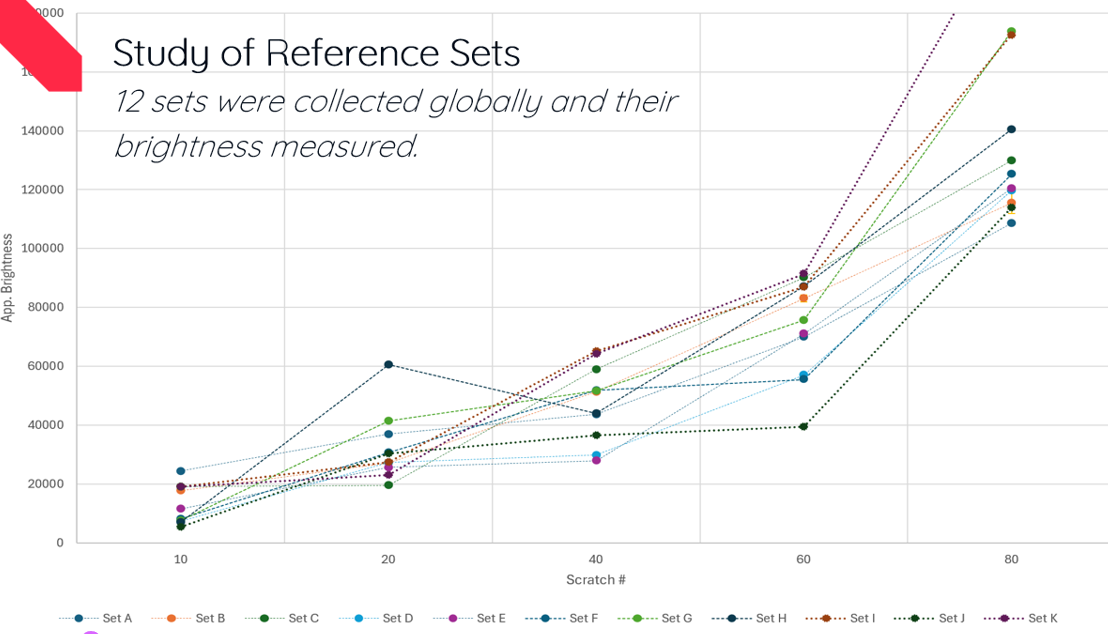

Recognizing the industry-wide, anecdotal dissatisfaction with existing standards, we conducted an in-depth study to assess variations in a widely used reference set from one manufacturer. 12 of these reference sets have been collected from users around the world and the brightness of each scratch measured under the same conditions. Figure 1 shows the measured values for of the sets A to K for each of the scratches #10 to #80.

Figure 1: Brightness of scratches on 12 commonly used reference sets.

The brightness of these scratches varies by a factor of 2 or more. A #10 scratch on one set may be as bright as a #40 scratch on another set. One set even has a #20 scratch that is brighter than the #40 scratch in the same set – something that is easily verified when inspecting the set by eye.

It is clear that a better solution is required if the optics industry is to trust the uniformity of the standards it uses. By developing an advanced technique for producing highly repeatable scratch-dig standards, we have achieved a significant improvement in standardization.

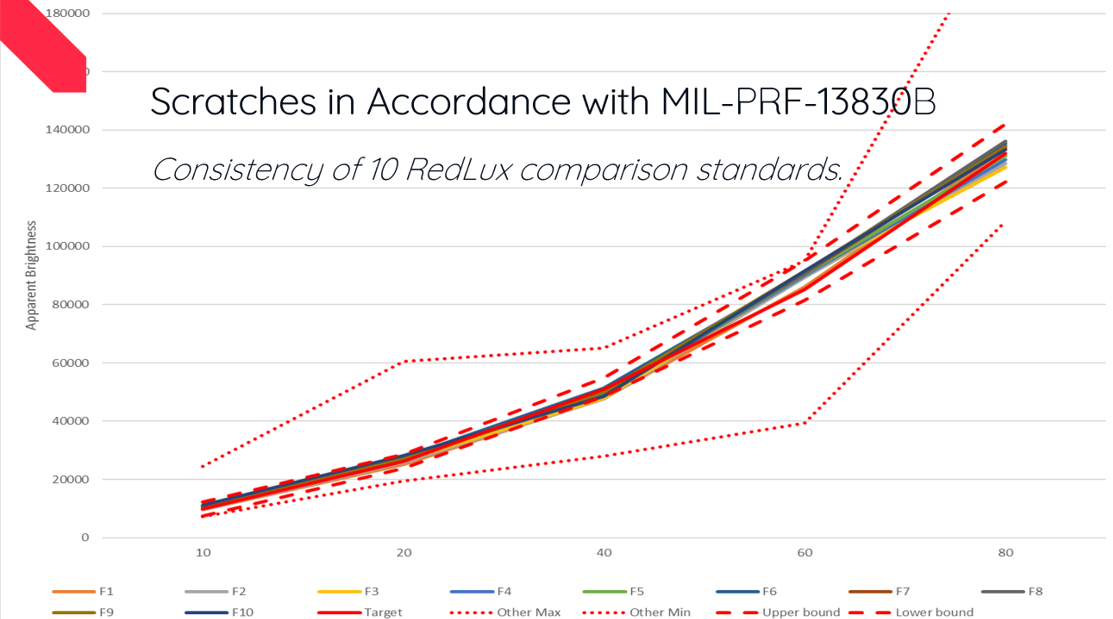

As illustrated in the data in Figure 2, our refined approach reduces variability and provides more consistent optical reference sets. The target line is derived from the theoretical equation in MIL-PRF-13830. The dotted line shows the maximum and minimum brightness found in the competitor sets from Figure 1, while the dashed line shows the upper and lower bound of the RedLux comparison standards across 10 standards, showcasing the effectiveness of this method. The result is a trustworthy reference system that enables inspectors across different departments and manufacturers to confidently apply consistent grading criteria.

The need for standardized and dependable reference sets is paramount to achieving fair and uniform inspection standards across the optics industry. By addressing long-standing repeatability challenges through rigorous study and precision manufacturing, RedLux has enhanced the reliability of scratch-dig inspection. This advancement strengthens quality control, reduces uncertainty in defect grading, and fosters trust between manufacturers and customers, ultimately benefiting the entire supply chain.

RedLux Scratch-Dig Comparison Reference Set

We’re helping organisations all over the world reap the benefits of world-leading metrology. Speak to our experts.