The MIL-PRF-13830B specification is a set of rules set out in 1997 by the Departments and Agencies of the Department of US Defence, and cover the manufacture, assembly and inspection of finished optical components such as lenses, prisms, mirrors, reticles, windows and wedges.

There are a number of defects that must be inspected for under this specification, however, there are two defect types identified as surface defects - "scratches" and "digs".

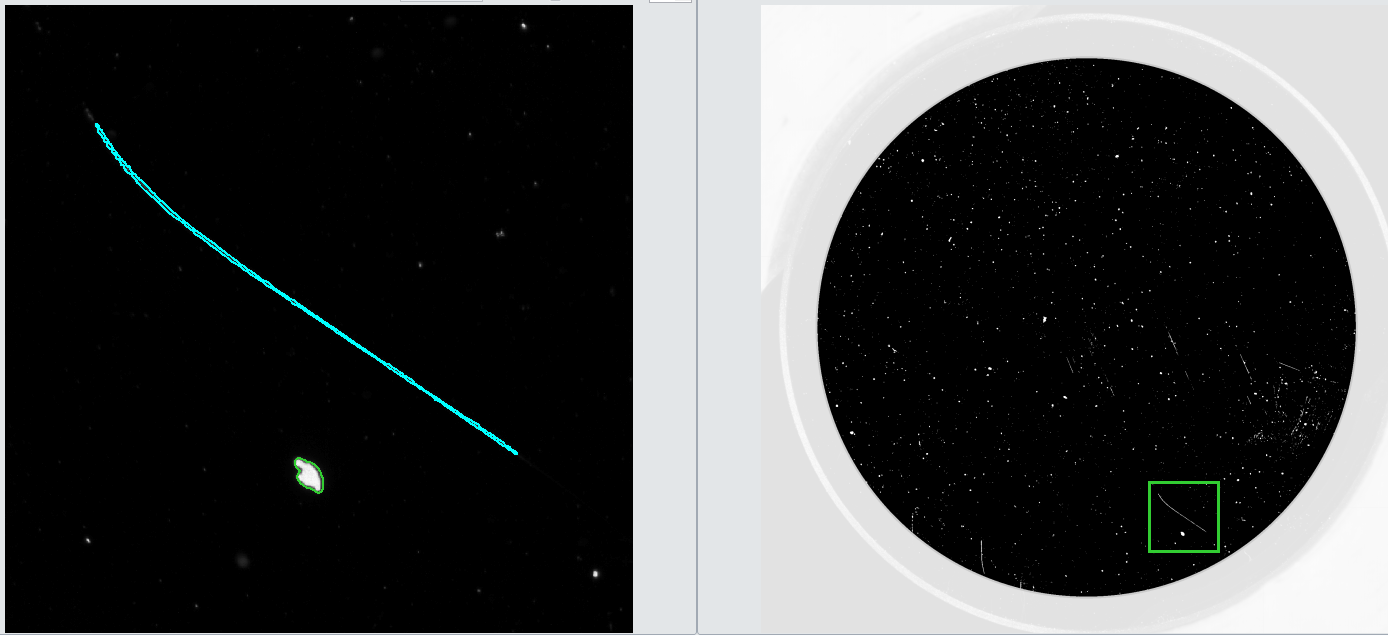

There is no definition of what separates a scratch from a dig in MIL-PRF-13830B, and so there is always room for interpretation. It is widely agreed that if a defect is considerable longer than it is wide then it is a scratch, and otherwise it is a dig. Inspection systems resolve this uncertainty by defining a threshold for separating scratches and digs. Below is an example of this.

Inspection results of a 1 inch optic. The left half showing a scratch and a dig, both clearly identified and differentiated between, the right half showing an overview of the optic after inspection.

Once a dig has been identified it has to be graded. According to section 3.5.3 of MIL-PRF-13830B, digs are graded in bands: 5, 10, 20, 40, 50. Digs are sorted into these bands based on their size, as the dig numbers are the diameters of the defects in units of 1/100 mm. This means that, unlike scratches under the same standard, it does not matter how visible the dig is. Often a dig will be an irregular shape that doesn't have a clear "diameter", in these cases the diameter is defined as the average of the maximum length and maximum width of the defect.

A given optical component will have a target grading it is produced to, denoted as "max scratch grade/max dig grade" e.g. 40/20, this means that if there are any digs with a grade of 20 or above, the part will be rejected.

While the concept of this definition is relatively straightforward, there are a few pitfalls that must be minimised in order to ensure optical components are being inspected accurately and consistently.

The first of these pitfalls is the reference set of digs that components are being compared to. Producing sets of digs that are consistent with each other is a considerable technical challenge that has caused issues in the industry for a number of years. Please click here for an overview of commercially available scratch dig comparison standards.

The second pitfall is that, as with all human based inspection, this method can be extremely subjective. Inspector's eyesight, lighting conditions and time of day can all have an impact on how a given dig can appear to an inspector. In recent years this issue has been overcome with the introduction of automated inspection machines. These systems can inspect optical components with consistent lighting and judgement, removing any subjectivity and producing unambiguous data for later reference.

The MIL-PRF-13830B specification provides a standardised way of grading defects and allows for manufacturers to guarantee component quality, however the inherent subjectivity in human inspection and the challenges of producing consistent reference standards mean care must be taken to ensure reliable and repeatable results are taken. The introduction of automated inspection systems has significantly improved this, reducing human error and ensuring compliance with the specification.

OptiLux SD Brochure

We’re helping organisations all over the world reap the benefits of world-leading metrology. Speak to our experts.