Edge chips are defined in sections 3.7.9.2 and 3.7.10.2 of MIL-PRF-13830B and 3.3, 4.2.1.5 and 4.3.1.3 of ISO 10110-7, with both standards agreeing that an edge chip is a section of missing material reaching from the outer edge of a part towards the centre.

If these edge chips reach into the optically active area of a part, they can have detrimental effects on the optical performance or, if a tight seal is required, on the sealing performance of the optic leading to rejection by the end customer. This means, it is important for manufacturers to consistently identify and grade edge chips, as even a single missed chip could cause a major failure for an end user.

Typically edge chips will be inspected for by eye, under the conditions set out by MIL-PRF-13830B or ISO 10110-7. This is generally sufficient for finding edge chips, however due to the number of associated rules in the industry standards, and the often small tolerances/distances worked with, it can be difficult for human inspectors to evaluate edge chips correctly, frequently leading to over-inspection and over-rejection of parts.

The alternative option is to use a machine vision solution to get around these challenges. The advantages of an automated system is that they can objectively identify each edge chip and accurately measure the defect size, even when working with distances too small for a human to quantify. A machine vision system can also consider all of the edge chips together, meaning no mistakes are made when dealing wth some of the accumulation rules. This results in more accurate and reliable inspection of optics and often leads to an increase in overall yield as many human inspectors end up over-inspecting parts out of caution.

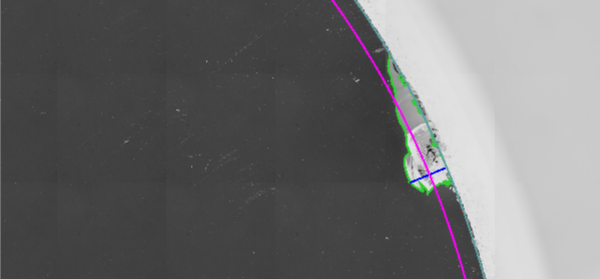

Our OptiLux SD is an automated surface quality inspection system that can automatically detect and grade scratches, digs and, with upgraded hardware, edge chips according to MIL-PRF-13830B, ISO 10110-7 or according to custom inspection criteria. The figure below shows an example of a part with edge chips after being evaluated by the OptiLux SD. It can clearly be seen that the system has detected where the edge of the part is (light blue curve), identified the presence of the edge chip (green outline of the chip) and then measured the dimensions of the chip (blue line). The OptiLux SD Inspect software suite will then automatically pass/fail the part based on both whether the chip extends too far into the optic, as well as the combined size of all the chips on the part (as per MIL-PRF-13830B 3.7.9.2).

Figure 1 - An edge chip detects and measured by the RedLux OptiLux SD as it would appear in the RedLux OptiLux SD Inspect software.

In conclusion, the inspection of optical components for edge chips is an important step in a manufacturer's quality assurance process that requires precision, accuracy and consistency. Traditional human based inspection methods are often limited by human error and the complexity of industry standards. Automated solutions such as the OptiLux SD from RedLux provide a reliable and objective alternative, ensuring that manufacturers can accurately identify and grade edge chips to ensure compliance with MIL-PRF-13830B and ISO 10110-7. By utilising machine vision, manufacturers can improve efficiency, help increase yield by reduction of false rejections, and overall deliver higher quality optics to their customers.

OptiLux SD Brochure

We’re helping organisations all over the world reap the benefits of world-leading metrology. Speak to our experts.